Reconstruction of other PIKO locos and cars to radio control and battery use |

After the unfortunate death of our gifted electronics technician Hannes the concept of radio controlled locos with battery packs and sounds self made stagnated for some years. However, the reconstruction with a sound control based on ARDUINO for instance is one of his sophisticated legacies.

|

It can be seen and heard on YouTube. Pictures of the reconstruction I didn't get, unfortunately, because Hannes didn't succed to get some.

Some model colleagues returned to machines controlled digitally. In the period of powerful little battery packs especially with LiFePO4 and good radio controls I don't want to do like that. Perhaps it may be the own convenience to clean all the tracks before driving. But all the productive talks with Hannes and the contacts with other colleagues of the model car, boats and planes made me realize that there are plenty of other fish in the sea.

A little juxtaposition may explain my decision pro radio control and contra digital control. The used radio control mz-32 HoTT 32 Kanal von GRAUPNER allows me to memorize more than 900 models. Surely, never mind, I don't anybody to have 1000 locos in his garden, but it shows the big redundancy inhereting in this system.

32 channels controlled by switches (digital controls have only 28 channels switched by a keyboard with 10 keys) with 3 switching modes for every channel allows a lot of switchable function to be carried out you couldn't remember on or limited by available power supply. However, the clou iss the sum signal whhere 64 digital driven switches can be operated which can even be combined in logical ways. The Soundmodul - which controls the model by a powerful enggine controler (30 A) - of BEIER Electronic with operational and 30 additional sounds hard to remember.

If I compare the cost of the different systems (june 2021) the most advantageous decision was easy to get. Radio control almost 1,000 Euros; on digital way the main digital device plus power supply - without power the system doesn't work - plus a handheld device and a receiver of the german company Massoth ca. 1,300 Euros. Then the costs per vehicle -- on my way the battery pack (ca. 6,000 mAh) plus the sound and engine controler plus some little things like cables, fuses, switch etc. ca. 350 Euros whereas digitally controlled by parts of the german company Massoth (surely the would be somewhat better parts to use) with power storage would cost nearly 300 Euros.

Let's loo into a tender of a german loco BR 50...

|

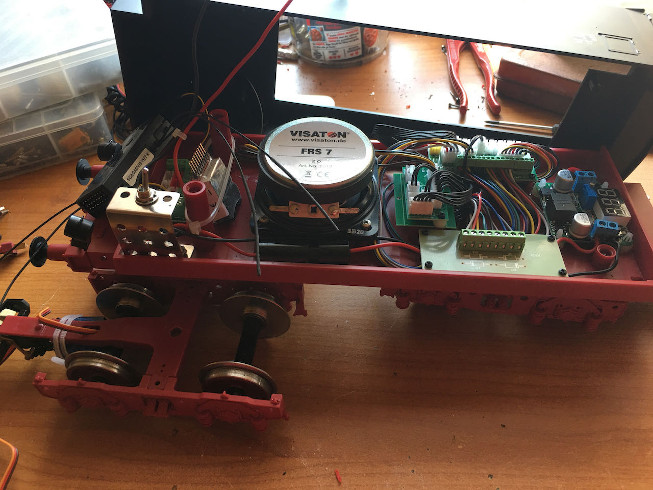

assembled tender with sound and engine controler SFR-1 without connections for servos and light

|

Now a short explanation of the main parts

|

1 - portable battery pack (LiFePO4, 6,000 mAh); 2 - main switch; 3 - receiver GR-32 HoTT2.4 GHz Dual 16 channel; 4 - main fuse 5 A; 5 - sound controler SFR-1; 6 - power controler; 7 - loud speaker FRS 7 of VISATON

|

assembled battery pack

coal cover

|

This was the next loco for a transformation

|

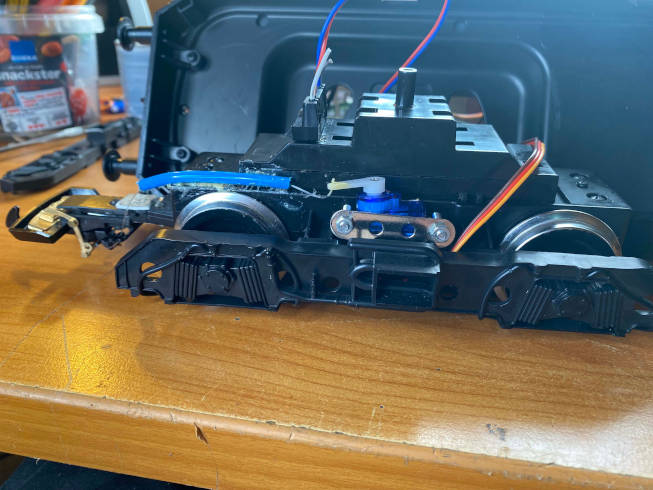

The trickiest part was locating the servo for the coupler. Due to the skirts, there wasn't much space, and I had to make sure that the bogie wouldn't be rotated out when uncoupling. It took six attempts to find the best location for the servo.

|

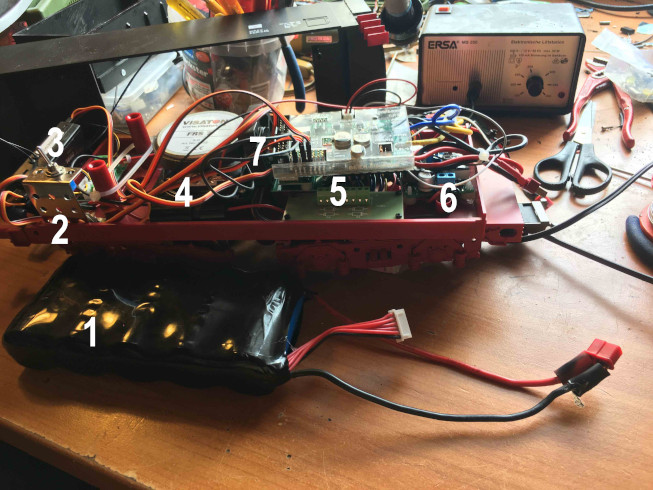

auch Diesel works well toogerman loco V 180 open

|

1 - battery pack stationary (NiMh 4,200 mAh)but due to a lack of power, it has now been replaced with a battery pack of 5 LiFePO4 cells 32650 with 5000 mAh; 2 - main switch; 3 - charging plug; 4 - loud speaker FRS 7 plus switch board; 5 - sound controler SFR-1; 6 - main fuse 5 A; 7 - receiver GR-32 HoTT2.4 GHz Dual 16 channel

Another machine has come to an end after starting several times. However, I had never had to deal with such difficulties before - the locomotive pushed me to my physical and technical limits, so much so that I was on the verge of breaking off twice. Original concepts regarding batteries or controls or the arrangement of the necessary components ended several times in the fruitless attempt to close the locomotive cleanly in the intended grooves with its narrow housing and the fact that the driver's cab sits in the middle .

But who also expects, for example, that Windows 11 will not be able to cleanly format micro SD cards, on which all sounds and control commands have to be saved, to Fat32 (an original Windows format!) - Beier electronics or Apple had to help out on the spot.

But it started with this:

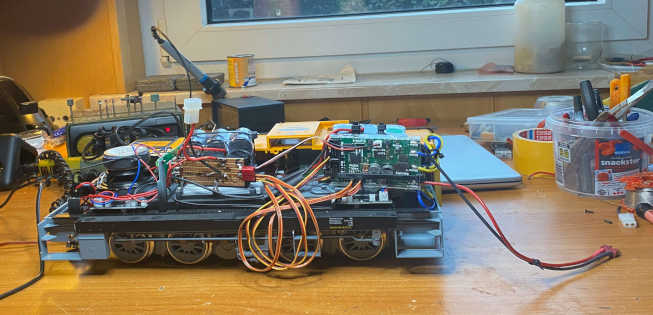

|

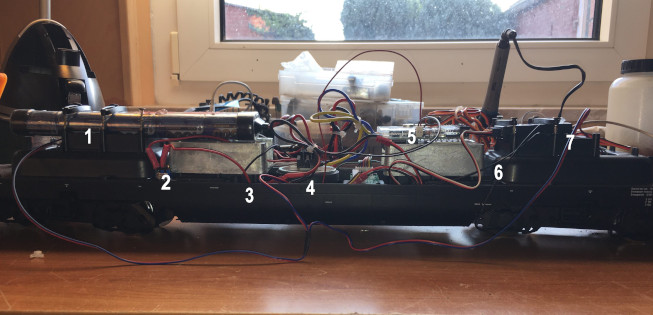

How do you bring 6000 mAh (after all, 2 motors and a sound module have to be fed with 5 W output power), speed controller with 70 x 40 x 10 mm, loudspeaker, terminal board (at least you should be able to keep track of all the connections) with all the cables under - that was almost the most difficult task. How do you store, for example, 8 patch cables each 15 cm long? This quickly leads to such chaos:

|

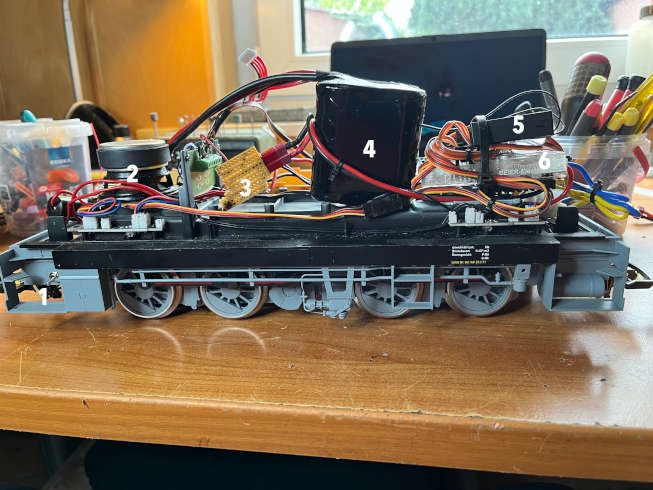

Short explanation: 1 - main switch, 2 - loudspeaker FRS 5, 3 - terminal board for all connections, 4 - battery block 4 cells LiCoMnO2, 5 - receiver Graupner GR-24 HoTT, 12 channel, 6 - sound speed controller SFR-1 from Beier electronics, Was which cannot be seen here are the servos for the uncouplers.

When closed it looks like this:

|

The lighting technology and motor connections remained original - the locomotive is practically "tricked" into thinking that it is on the track in analogue operation. Only all rail grinders and the carbon brushes with connection contact on the gearbox had been removed. There is therefore no longer any contact with the track.

Finally everything fit and the little machine was able to take possession of its fold-proof transport case.

|

and outside as a Premiere for this year - 2023 - opening the season.

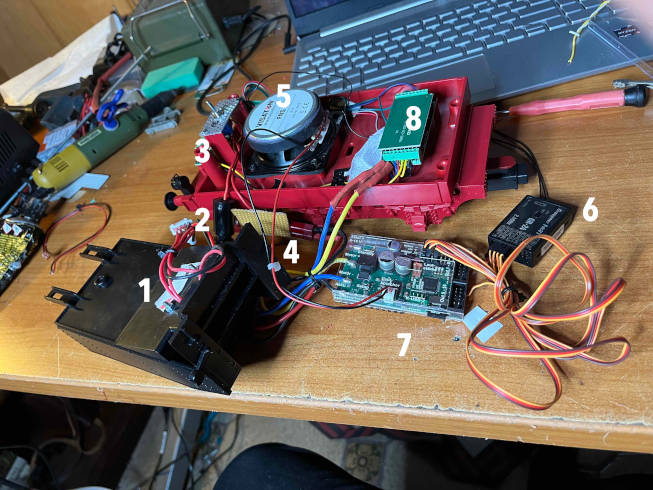

In May there was still a bit of tinkering when it came to putting an additional battery-powered machine on the rails in time for the Schkeuditz large railway meeting. The choice was the class 24 from PIKO. Her tender offered enough space for all necessary components.

|

Brief explanation of the main components: 1 - Battery block of 4 LiCoMnO2 cells 26650 5000 mAh in the coal box; 2 - main fuse 5 A; 3 - main switch; 4 - clipboard; 5 speakers Visaton FRS 7; 6 - receiver Graupner GR-24 HoTT, 12 channel, 7 - sound speed controller SFR-1 from Beier electronics; 8 - Piko main board with the possibility of track connections.

This locomotive also has its playpen:

|

Quick programming of the SFR 1 via USB on a garden railway layout of a friend:

|

Irony of fate - in Schkeuditz she wasn't allowed on the track - supposedly she was too loud. But then the journey remained on the home layout on a beautiful summer evening.

Bei all discussions about pro and con - I'm the opinion that this is conclusive and simple realizable solution resulting from all my experiences summed up during the last 10 years.

At this point I would like to emphasize again that it won't work without reading the operating instructions, a basic backup of the technology using appropriate circuit breakers and main fuses, the care of the built-in batteries according to the specifications due to their chemistry and the fact that technology quickly says farewell, if you don't give it the attention it deserves.

In addition to a clean consumption analysis it all starts with not using cheap chargers or knowing what balancing means for charging. One should always remember that a lot of energy is stored here in a small space, which can also be discharged spontaneously. In other words, you can repurpose any engine into a steam engine, at least once. Physics or chemistry can be relentless when dangerous half-knowledge is involved.

If you always keep this in mind, the technology can surprise you in a positive way, even if it is only that the batteries still have their full capacity after a year of non-operation.

In this sense a lot of fun with our common sense!

© Bahnrolli 08/10/2025 | Sitemap